Top 3 Homebuilding Blind Spots You Didn’t Know You Had

Blind spots are just that – an area you can’t see. Here are some of the most common home builder blind spots we see.

Blind spots are just that – an area you can’t see. Danger sometimes lurks within these blind spots. Thank goodness for back-seat drivers who point them out to us – usually by screaming and making us crazy.

Blind spots happen in business as well; we just don’t have a back seat driver to point them out to us.

In our close work with homebuilders, we’ve learned that the top three blind spots are hidden in HVAC design, moisture management, and warranty departments.

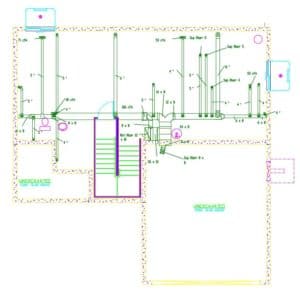

HVAC Design

Improper HVAC design can lead to increased comfort complaints, over spending on equipment, and even moisture-related building failures.

Many code jurisdictions are placing added emphasis on HVAC Design during the permit application. This results in more permits being rejected and additional delays for the builder.

Now that somebody is paying attention to the designs, we should expect reduced comfort complaints and callbacks, right? Unfortunately not.

Many plan reviewers lack the necessary skill and training to properly review HVAC designs or they’re too busy to do a thorough review. At best, they are most likely catching inconsistencies between the design and other permit documents.

Beyond getting through permit review, a great design is worthless if it can’t be installed.

What many builders don’t realize is that the design they submit for permitting rarely matches the actual installation.

In the field, the installers often make their own modifications to work around plumbing, structural components and other unforeseen obstacles.

How will the added turns and elbows impact air flows?

Will the system still work?

Does anyone bother to check with the designer, or do we just shrug and hope for the best?

If you've faced these problems and want to improve your process, great news! EnergyLogic offers HVAC design services.

Moisture Management

Mold growth and water stains on the ceiling of an abandoned house

It is estimated that $9-10 billion is spent every year to correct construction defects.

Eighty percent of those defects are moisture-related. (By the way, 100% of them passed code.)

Often, moisture problems that lead to these failures could have been prevented with simple quality control. However, you can’t depend on your code inspector to ensure proper flashing and drainage.

Deterioration of building components, including wall sheathing, siding, trim, framing, and other structural components lead to high warranty costs and potential lawsuits.

Few builders employ third party inspectors that focus on moisture management and drainage. Busy site superintendents are spending less and less time in each home. This means that most builders expect their trade partners to police themselves. Based on our conversations with construction defect lawyers and what we observe in the field every day, that strategy just isn’t cutting it.

Warranty Department

Experience tells us that most warranty departments are ill-prepared to diagnose and solve comfort or moisture-related problems, and are wasting time and money by not resolving problems efficiently.

Sometimes the attempted fixes involve major time and expense and still don’t solve the problem. That’s like prescribing surgery without a diagnosis.

More importantly, customer satisfaction suffers when call-backs require three or more visits before being resolved.

Finally, in our experience, Warranty departments in larger operations do not always work closely enough with those on the operational side. That means precious time elapses, resulting in many more problem homes which are constructed with the same defects, before new practices can be implemented in the field.

If you are interested in learning more about ways to reduce builder risk, contact us.

About the Author

This piece was written by Scott Doyle. Scott was one of EnergyLogic's first employees, starting in 2006. After over 10 wonderful years, Scott was hired by RESNET as their Quality Assurance Contractor Manager. Scott truly embodies EnergyLogic's "Growing Experts" philosophy!

This piece was written by Scott Doyle. Scott was one of EnergyLogic's first employees, starting in 2006. After over 10 wonderful years, Scott was hired by RESNET as their Quality Assurance Contractor Manager. Scott truly embodies EnergyLogic's "Growing Experts" philosophy!