Goodbye to Guarded Blower Door Testing

Standards are changing. How will you pass your next blower door test? Find out what is, and is not, allowed moving forward.

Published April 26, 2021

Compliance Methods Have Changed

RESNET has adopted ANSI/RESNET/ICC 380-2019 for homes permitted after April 1, 2021. The standard states specifically in section 4.3.2.1 that "Pressures shall be induced only via a Blower Door (or Blower Doors) attached to the subject Dwelling Unit. Pressures shall not be induced through the use of Blower Doors attached to spaces adjacent to the subject Dwelling Unit." This means that a method that energy raters and other testing agencies have had in our back pocket (known as "guarded blower door testing") to help get individual units to pass the required blower door test is no longer allowed.

More importantly, builders and project teams must "compartmentalize" individual units much more thoroughly to get them to pass the code-mandated requirements. This will make it much more critical for your project teams. Starting with the architectural drawings, look at these air separating details very closely.

Energy Codes vs. Fire Codes

For years there has been a disconnect between energy codes and fire codes. What is allowed and mandated in the fire code section, or the International Residential Code (IRC) or the International Building Code (IBC), overrides concerns of the building envelope testing required by the International Energy Conservation Code (IECC). For a good reason, building officials have enforced these assemblies being built exactly as the Underwriters Laboratories (UL) or General Arrangement (GA) details outline. Nothing can be added to these walls, including additional foam. They have only been tested and certified to function at their rated time in a fire with the very specific components listed in the design.

For many years no assembly had been approved to use foam inside of these walls. UL has recently certified two wall types:

1.) the 373 non-bearing, and

2.) 375 bearing wall types

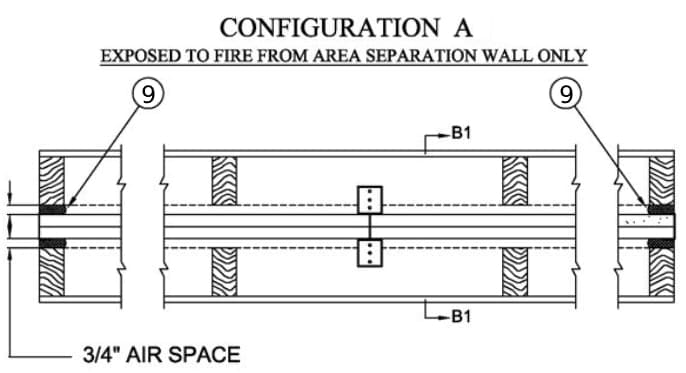

These are a traditional shaft wall type assembly with two layers of an approved 1" fire-rock material, with framed walls on each side of the assembly with a typical ¾" gap. This gap in the previously listed walls was only allowed to have an approved fire blocking material. These did not include any foam sealant-type materials. These listings now specifically enable the following to be used at detail 9:

- DUPONT DE NEMOURS, INC. — Great Stuff Gaps & Cracks, Great Stuff Pro Gaps & Cracks, Great Stuff Pro Window & Door

- ICP ADHESIVES & SEALANTS INC — Handi-Foam Fireblock, Handi-Foam Fireblock West, and Fast Foam Fireblock

Image source, UL Product IQ, 375

Attention to Detail is Key

Project teams and architects usually specify what type of wall to install. They need to be mindful of their choice of wall assembly as this can be one of the main contributors to failing building envelope testing. The good news is they now have more options to choose from that allow compliance with both fire and energy codes.